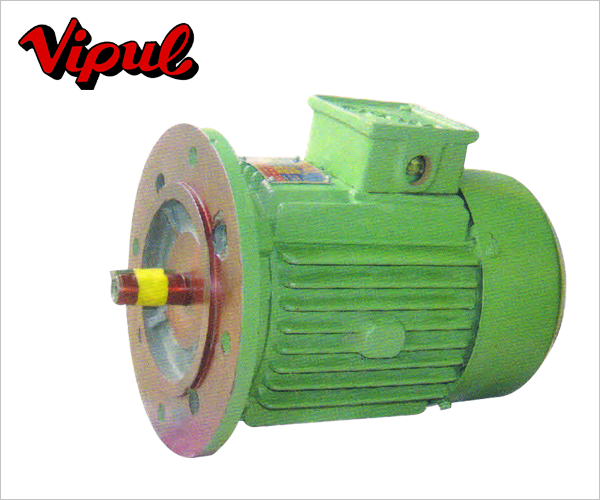

Electric Motor

Discription:

SPECIFICATION & PERFORMANCE:-

Motors are continuously rated s1 duty, suitable for 415 volts +- 6%, 50 c/s +- 3%, three phase A.C. supply with class “b” insulation, ambient temperature of 40c and site altitude of up to 1000m above mean sea level. All T.E.F.C. squirrel cage motors comply with IS: 325 & dimension according to IS: 2223.

RANGE:- Standard three phase 0.125 HP to 20 HP (0.09 KW to 15KW) , Frame size 56 to 160 L IN 2,4,6 AND 8 pole design. Single phase motors 0.25 H.P.TO 3 H.P.

ENCLOSURE:- Motors have IP-44 protection as defined in IS: 4691. MOTORS can be supplied with IP-54 AND IP-55 on request which provides protection against damaging ingress of dirt and harmful effects of water jet.

CONSTRUCTION:- Standard motors with single shaft extension are horizontal foot mounted.

INSULATION SYSTEM AND WINDING PROTECTION :-Motor are provided with class “b” insulation system, class “f” can be supplied on request PTC thermostats in the stator winding can be supplied on request.

PRESSURE DIE-CAST ROTORS:- All rotors are of high pressure aluminum die-cast to ensure improved reliability due to elimination of joint that exist in a brazed rotor. Each rotor is dynamically balanced along with the fan on electronic machine to ensure very low amplitudes of vibration and noise level.

TERMINAL BOX:- Standard location of the M.S. terminal box with two cable conduct entries is on the side of the housing.

NOISE LEVEL AND VIBRATION: - Motors are designed for low noise level. Dynamically balanced having perfect alignment and a fine control on the uniformity of air gap minimize the vibration. Pulley, bearing seats and air gap surfaces are grinding resulting in vibration free running.

BERING SYSTEM:- Bearing is anti-fraction ball and roller bearings. Re-greasing can be provided on request. The grease used and recommended is lithium based with drop point greater than 1600.

EARTHING TERMINALS:- All motors have three earthing terminals. One in the terminal box and one on each foot.

LIFTING HOOKS:- Suitably located hooks of adequate strength are provided to lift the motor bodily for the purpose of installation, alignment, repairs and overhauling etc.

PAINT:- All standard motors are painted with semi-glossy synthetic enamel paint. However special paint is available on request.

RELEVANT ISI STANDARD TO MOTORS

- IS: 325 Specification of 3 phase induction motors.

- IS: 2971 PART -1, specification for textile motors-loom

- IS: 1231 Dimension of 3 phase foot mounted motors.

- IS: 2223 Dimension of 3 phase flange mounted motors.

- IS: 2253 Types of construction & mounting of motors.

- IS: 4691 Degree of protection provided by enclosure electrical machines.

- IS: 4029 Guide for testing 3 phase induction motors.

- IS: 4889 Methods of determination of efficiency of rotating electrical machines.

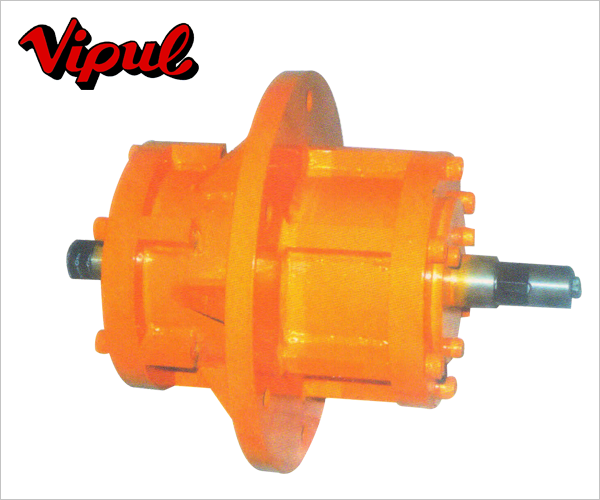

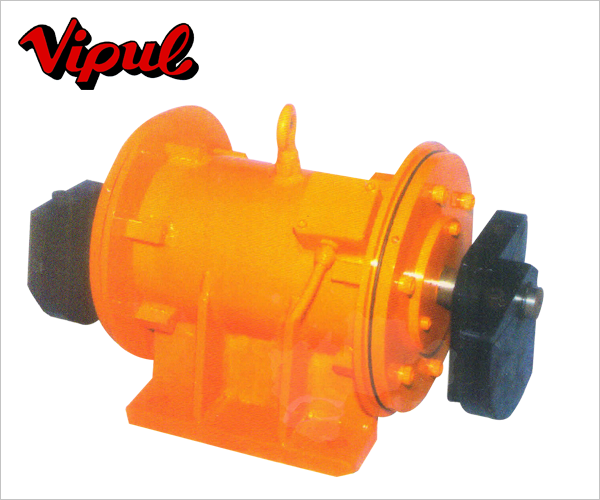

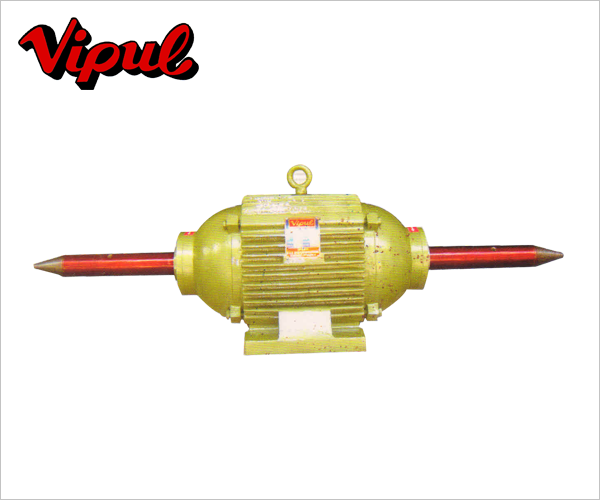

VIBRATORY MOTORS

Discription:

GENERAL:-Unbalance motors are a synchronous ac motors with pairs of centrifugal weights fitted to the ends of the motor shafts. The size of the unbalance and with it the amplitude weight the motor is at a standstill. The unbalance motors are also available in special version for mains voltages up to 440V and for a mains frequency ranging from 50 Hz to 60 Hz.

Unbalance vibratory motor with special tough design is used us drive for the vibrating machines. The applications are feeding, screening, discharging, conveying etc. The vibration motors are available in 2800, 1400, 960, and 750 RPM. The special features includes sturdy frame with stiffing ribs, body fabricated with high grade ductile iron, extra large die, of shaft to resist banding under high centrifugal force. Fitted with heavy duty cylindrical roller bearings, specially varnished winding with terminal box to withstand tough operating condition, specially designed electrical parameters for cool operation conditions. vibration motors are available from 0.25 hp to 10 hp in foot mounted design or flange mounted type vibration mounted are widely used in process plants, glass ,food, metal, goal power plant, chemical, ceramic, iron and steel, foundries, packaging industries etc.

DIMENSIONAL DETAILS

| MODEL NO. | POWER INPUT HP | PCD | MOUNTING HOLE DIA.X NOS OF HOTELS. |

| VM-FVB-01 | 0.25 | 160 | 14MM*6NOS. |

| VM-FVB-02 | 0.50 | 180 | 14MM*6NOS. |

| VM-FVB-03 | 1.00 | 230 | 15MM*6NOS. |

| VM-FVB-04 | 2.00 | 230 | 22MM*6NOS. |

| VM-FVB-05 | 3.00 | 270 | 22MM*6NOS. |

| VM-FVB-06 | 5.00 | 300 | 27MM*6NOS. |

| VM-FVB-07 | 7.00 | 360 | 27MM*6NOS. |

| VM-FVB-08 | 10 | 400 | 27MM*6NOS. |

DIMENSIONAL DETAILS

| MODEL NO. | POWER INPUT HP | A | B | MOUNTING HOLE DIA.X NOS OF HOLES | MOC. CENTRIF FORCE KGS. |

| VM-FVB-01 | 0.25 | 80 | 85 | 12.5MM*4 NOS. | 350 |

| VM-FVB-01 | 0.50 | 0 | 85 | 15MM*4NOS | 750 |

| VM-FVB-01 | 1.00 | 140 | 108 | 17MM*4NOS. | 1800 |

| VM-FVB-01 | 2.00 | 152 | 130 | 21MM*4NOS | 3500 |

| VM-FVB-01 | 3.00 | 152 | 130 | 25MM*6NOS | 4500 |

| VM-FVB-01 | 5.00 | 210 | 170 | 25MM*6NOS | 5500 |

| VM-FVB-01 | 7.50 | 280 | 200 | 27MM*6NOS | 9000 |

| VM-FVB-01 | 10 | 300 | 235 | 27MM*6NOS | 12000 |

- CENTRIFUGAL FORCE VALAVE AT50HZ

- ALL DIMENSIONS ARE IN MM

BENCH GRINDER

Discription

SALIENT FEATURE

- C.I casting of high grade quality.

- Use of best quality stamping and die cast rotor.

- Motor winding are specially insulated and impregnated with high grade insulting varnish to withstand humid.

- Moist and tropical climate.

- Dynamically balanced rotor minimizes vibrations and ensure smooth running.

- Each machine provided with rotary switch

- The wheel guards are provided on bench grinders with end caves, which may be easily removed for fitting of grinding wheels. They give perfect protection to the worker with full freedom of operations.

- Adjustable tool resets are provided to ensure maximum usage of grinding wheels. Tool resets are machined to give proper level to the grinding component.

- Construction of the machines is made sturdy and robust to offer vibration free performance.

- Confirms to IS 2538 standard

- Use of high quality grease for lubrication, recommended lithon 3 of hp or equivalent

- All machines are subject to rigid quality control tests.

- Machines of different voltage and different frequency can be supplied against specific orders.

- One year warranty against any manufacturing defect.

- Bench grinders up to 2 H.P. rating are supplied with eye shield. The same can be supplied at extra cost.

SPECIFICATIONS OF BENCH GRINDERS & POLISHERS

THREE PHASE BENCH GRINDER & POLISHER

| NO. | K.W. | H.P. | R.P.M | WHEEL SIZE |

| 1 | 0.09 | 0.125 | 3000 | 6” *1/2” |

| 2 | 0.18 | 0.25 | 3000 | 6”*1/2” |

| 3 | 0.37 | 0.50 | 3000 | 8”*1/2” |

| 4 | 0.55 | 0.75 | 3000 | 8”*1/2” |

| 5 | 0.75 | 1.00 | 3000 | 10”*1/2” |

| 6 | 1.50 | 2.00 | 3000 | 12”*1/2” |

| 7 | 1.50 | 2.00 | 1500 | 12”*1 ½” |

| 8 | 2.2 | 3.00 | 3000 | 12”*1 ½” |

| 9 | 3.7 | 5.00 | 3000 | ----- |

SINGLE PHASE BENCH GRINDER & POILISHER

| NO. | K.W. | H.P. | R.P.M | WHEEL SIZE |

| 1 | 0.09 | 0.125 | 3000 | 6”*1/2” |

| 2 | 0.09 | 0.125 | 3000 | 6”* ¾” |

| 3 | 0.18 | 0.25 | 3000 | 6” * ¾” |

| 4 | 0.37 | 0.50 | 3000 | 8” * ¾” |

| 5 | 0.55 | 0.75 | 3000 | 8”* 1” |

| 6 | 0.75 | 1.00 | 3000 | 10” * 1” |

| 7 | 1.50 | 2.00 | 3000 |

FLEXIBLE SHAFT GRINDERS

| TYPE | K.W. | H.P. | R.P.M |

| SINGLE PHASE | 0.75 | 1 | 3000 |

| THREE PHASE | 0.75 | 1 | 3000 |

| THREE PHASE | 1.5 | 2 | 3000 |

NIDDLE VIBRATOR MACHINE

Discription:

- Designed to suit all types of site conditions, the high frequency of 16000 vibe / min, ensures use for perfect concrete mixture different grades.

- SPECIFICTION :-

Needle: 25mm,40mm,60mm

Flexible shaft 4m or 6m in length

2hp single phase motor>

3hp three phase motor

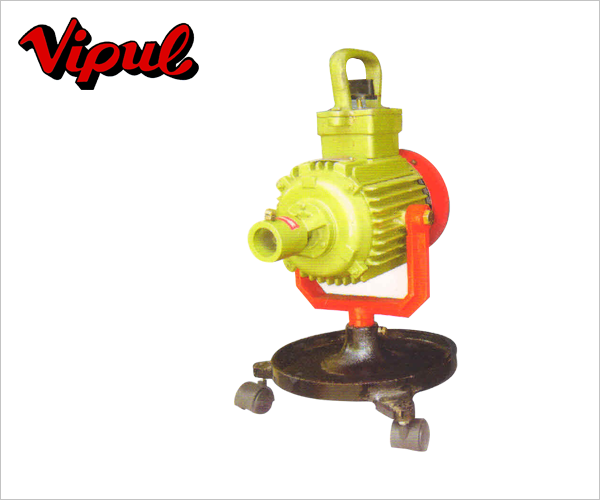

FLEXIBLE SHAFT GRINDER

Discription:

- Designed to suit all types of site conditions, the high frequency of 16000 vibe / min, ensures use for perfect concrete mixture different grades.

- SPECIFICTION :-

Needle: 25mm,40mm,60mm

Flexible shaft 4m or 6m in length

2hp single phase motor>

3hp three phase motor

PEDENTAL GRINDER MACHINE

Discription:

- Pedestal grinding machine with standard size pedestal stand. The pedestal stand is c.i. casting of high grade quality and it is suitable for all size grinder machines.

- Construction of the machine is made sturdy and robust .To offer vibration free performance.

S. S. UTENSILE POLISHER

Discription:

Specially used in polishing of S.S. Utensils

3H.P. to 5 H.P.